Wiring & diagram Info

Monday, January 26, 2015

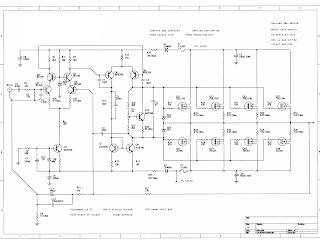

Stereo Preamplifier With Bass Boost

This preamplifier was designed to cope with CD players, tuners, tape recorders etc., providing an ac voltage gain of 4, in order to drive less sensitive power amplifiers. As modern Hi-Fi home equipment is frequently fitted with small loudspeaker cabinets, the bass frequency range is rather sacrificed. This circuit features also a bass-boost, in order to overcome this problem. You can use a variable resistor to set the bass-boost from 0 to a maximum of +16dB @ 30Hz. If a fixed, maximum boost value is needed, the variable resistor can be omitted and substituted by a switch.

Stereo Preamplifier With Bass Boost Circuit diagram:

P1 = 10K

P2 = 100K

R1 = 100K

R2 = 100K

R3 = 15K

R4 = 10K

R5 = 22K

R6 = 15K

R7 = 1K

R8 = 470R

C1 = 2.2uF-25v

C2 = 2.2uF-25v

C3 = 470uF-35v

C4 = 1uF-35V

C5 = 2.2uF-25v

C6 = 47nF-63v

C7 = 22uF-25v

IC1 = TL072, Opamp

SW1 = DPST Switch

Notes:

- Schematic shows left channel only, but R1, R2, R3 and C1, C2, C3 are common to both channels.

- For stereo operation P1, P2 (or SW1), R4, R5, R6, R7, R8 and C4, C5, C6, C7 must be doubled.

- Numbers in parentheses show IC1 right channel pin connections.

- A log type for P2 ensures a more linear regulation of bass-boost.

- Needing a simple boost-in boost-out operation, P2 must be omitted and SW1 added as shown in the diagram.

- For stereo operation SW1 must be a DPST type.

- Please note that, using SW1, the boost is on when the switch is open, and off when the switch is closed.

12V Flourescent Lamp Inverter

Fluorescent tubes use far less energy than incandescent lamps and fluorescent tubes last a great deal longer as well. Other advantages are diffuse, glare-free lighting and low heat output. For these reasons, fluorescent lighting is the natural choice in commercial and retail buildings, workshops and factories. For battery-powered lighting, fluorescent lights are also the first choice because of their high efficiency. The main drawback with running fluorescent lights from battery power is that an inverter is required to drive the tubes.

12V Fluorescent Lamp Inverter Circuit diagram:

Fig.1: two switch-mode circuits are involved here: the DC-DC inverter involving IC1, Q1 & Q2 and the fluoro tube driver which converts high voltage DC to AC via IC3 and Q3 & Q4 in a totem-pole circuit.

Inverter efficiency then becomes the major issue. There are many commercial 12V-operated fluorescent lamps available which use 15W and 20W tubes. However, it is rare to see one which drives them to full brilliance. For example, a typical commercial dual 20W fluorescent lamp operating from 12V draws 980mA or 11.8W. Ignoring losses in the fluorescent tube driver itself, it means that each tube is only supplied with 5.9W of power which is considerably less than their 20W rating. So while the lamps do use 20W tubes, the light output is well below par.

Warning:

This circuit generates in excess of 300V DC which could be lethal. Construction should only be attempted by those experimenced with mains-level voltages and safety procedures.

Thursday, November 20, 2014

3 Channel Audio Mixer Circuit

Although the modular Portable Mixer architecture accessible on these web pages has become a hit for abounding amateurs, some correspondents appropriate a abundant simpler device, mainly for bond address signals.

This architecture should fulfil their needs, featuring three inputs with switchable high/low acuteness and abnormal level-control circuits, accouterment aerial afflict margins and low-noise figures, proportional to gain-level settings. Low accepted burning due to a simple, five-transistor circuitry, allows the Mini Mixer to be powered by a accepted 9V PP3 array for abounding hours.

This architecture should fulfil their needs, featuring three inputs with switchable high/low acuteness and abnormal level-control circuits, accouterment aerial afflict margins and low-noise figures, proportional to gain-level settings. Low accepted burning due to a simple, five-transistor circuitry, allows the Mini Mixer to be powered by a accepted 9V PP3 array for abounding hours.

X Ray Protector Circuits

A protector system that is applied at the beginning of the television technique, therefore most often found on old aircraft models. If the high voltage anode of the picture tube flyback tranfo exceed the permitted limit, the picture tube can generate x-rays from the anode and shadowmask are bombarded by electrons at high speed. To avoid this problem then mounted x-ray surge protector circuit , which automatically "horizontal section will be turned off" if the high voltage from the flyback over.

| X-Ray vertical protect |

The workings of x-ray protector:

- High voltage flyback sampled (generally taken from the pin-heater), rectified and is derived using a divider (devider) that uses a resistor-type high-precision resistor. Sample voltage is used to determine whether the condition is normal flyback voltage or over.

- A "zener diode" as a voltage sensor connected to the sample. In normal conditions the amount of the sample voltage is below the zener voltage of diode so that the condition "off" or is not transparent.

- Suppose there is a sudden event increased flyback voltage - the voltage will rise above the sample diode voltage value, which causes the diode "on" or voltage through the diode, which would trigger protectionist active work.

Problems that can lead to x-ray active protector works:

- Damage that causes the power supply voltage B + or incorrect adjustment over

- Resonant capacitor to the collector of transistor HOT off the decline or solder

- Tranfo replacement flyback mounted do not match.

- Damage to one part in the sensor circuit protectors x-ray alone

| X-ray Protect Circuit |

230 400 Watt Power Amplifier MOSFET

Amplifier circuit below is a series of amplifiers with the amplifier transistor and mosfet. This amplifier output power ranging from 230W up to 400W.

|

| 230 - 400 Watt Power Amplifier |

Egg incubator comtrol list Program

List Program Temperature Controller AT89C2051 egg incubator is a program used to control the temperature control device incubator Egg With AT89C2051 which details a series of articles exist on Temperature Controller With AT89C2051. Many requests are asking for the program lists a series Temperature Controller AT89C2051 egg incubators. Hopefully with the upload list of programs from a series Temperature Controller AT89C2051 egg incubators can help and give inspiration to all who are looking teman2 reference to the construction of the Temperature Controller egg incubators. Temperature Controller program listings AT89C2051 Egg incubators that I uploaded are still many shortcomings, so it can be developed more to get better. Following the program listings.

List Program Temperature Controller AT89C2051 Egg incubators

ORG 0h

Coma EQU 30h

UNIT EQU 31H

Dozens EQU 32H

HUNDREDS EQU 33H

MENU_OK EQU 34H

D_SETING1 EQU 35H

D_SETING2 EQU 36H

D_DISPLAY1 EQU 37H

D_DISPLAY2 EQU 38H

D_TEMPERATURE1 EQU 39H

EQU D_TEMPERATURE2 3AH

REVERSE EQU 3BH

REST EQU 3CH

T_MENU BIT P3.0

T_DOWN BIT P3.1

T_UP BIT P3.2

LAMP BIT P3.3

P_TEMPERATURE BIT P3.4

P_ZX BIT P3.5

ACALL SET_AWAL

START: ACALL TEMPERATURE

ACALL MENU

ACALL APPEAL

ACALL CONVERSION

JMP START

TEMPERATURE: MOV R3, # 64H

MOV TMOD, # 15H

MOV TL0, # 00H

MOV TH0, # 00H

SETB TR0

AGAIN: MOV TL1, # 0EFH

MOV TH1, # 0D8H

SETB TR1

ACALL CONVERSION

WAIT: JNB TF1, WAIT

CLR TR1

CLR TF1

DJNZ R3, AGAIN

CLR TR0

CLR TF0

END_T: MOV D_TEMPERATURE1, TL0

MOV D_TEMPERATURE2, TH0

MOV D_DISPLAY1, D_TEMPERATURE1

MOV D_DISPLAY2, D_TEMPERATURE2

ACALL CONVERSION

END_TEMPERATURE: RET

MENU: JB T_MENU, CHECKING_MENU

ACALL DELAYT

ACALL DELAYT

MOV A, MENU_OK

CJNE A, # 0h, SETING_OK

MENU_OK MOV, # 1H

JMP UP

SETING_OK: MOV MENU_OK, # 0h

JMP END_MENU

UP: JB T_UP, DOWN

MOV A, MENU_OK

CJNE A, # 1H, MENU

ACALL DELAYT

D_SETING1 INC.

MOV D_DISPLAY1, D_SETING1

MOV D_DISPLAY2, D_SETING2

ACALL CONVERSION

MOV A, D_SETING1

CJNE A, # 0FFH, UP

CLR D_SETING1

D_SETING2 INC.

MOV D_DISPLAY1, D_SETING1

MOV D_DISPLAY2, D_SETING2

ACALL CONVERSION

DOWN: JB T_DOWN, MENU

MOV A, MENU_OK

CJNE A, # 1H, MENU

ACALL DELAYT

MOV A, D_SETING1

CJNE A, # 00D, less_LSB

MOV A, D_SETING2

CJNE A, # 00D, less_MSB

JMP MENU

less_LSB: DEC D_SETING1

MOV D_DISPLAY1, D_SETING1

MOV D_DISPLAY2, D_SETING2

ACALL CONVERSION

JMP DOWN

less_MSB: DEC D_SETING2

MOV D_SETING1, # 0FFH

MOV A, D_SETING1

DA A

MOV D_DISPLAY1, D_SETING1

MOV D_DISPLAY2, D_SETING2

ACALL CONVERSION

JMP DOWN

CHECKING_MENU: MOV A, MENU_OK

CJNE A, # 0h, SETTINGS

JMP END_MENU

SETTINGS: MOV D_DISPLAY1, D_SETING1

MOV D_DISPLAY2, D_SETING2

ACALL CONVERSION

JMP UP

END_MENU: RET

APPEAL: MOV A, D_SETING1

CJNE A, D_TEMPERATURE1, CHECKING1

JMP B_MSB

CHECKING1: SubB A, D_TEMPERATURE1

JC B_MSB

JMP LIFE

B_MSB: MOV A, D_SETING2

CJNE A, D_TEMPERATURE2, CHECKING2

JMP STOP

CHECKING2: SubB A, D_TEMPERATURE2

JC SWITCH

JMP END_B

SWITCH: SETB LAMPS

END_B: RET

CONVERSION: MOV R1, D_DISPLAY2; MSByte

MOV R2, D_DISPLAY1; LSByte

MOV R4, # 00D

MOV R5, # 00D

MOV R6, # 00D

MOV R7, # 00D

MOV B, # 10D

MOV A, R2

DIV AB

MOV R4, B; 7,6,5,4 BCD DATA IS

MOV B, # 10

DIV AB

MOV R5, B

MOV R6, A

CJNE R1, # 0h, HIGH_BYTE; CHECK FOR HIGH BYTE

SJMP END_KONVERSI

HIGH_BYTE: MOV A, # 6

ADD A, R4

MOV B, # 10

DIV AB

MOV R4, B

ADD A, # 5

ADD A, R5

MOV B, # 10

DIV AB

MOV R5, B

ADD A, # 2

ADD A, R6

MOV B, # 10

DIV AB

MOV R6, B

ADD A, R7

DA A

MOV R7, A

DJNZ R1, HIGH_BYTE

END_KONVERSI: MOV coma, R4

MOV UNITS, R5

MOV tens, R6

HUNDREDS MOV, R7

ACALL DISPLAY

RET

DISPLAY: MOV A, coma; Segment 1

ADD A, # 10H

SWAP A

MOV P1, A

ACALL DELAY

MOV A, UNIT; Segment 2

ADD A, # 20h

SWAP A

MOV P1, A

ACALL DELAY

MOV A, tens; Segment 3

ADD A, # 40H

SWAP A

MOV P1, A

ACALL DELAY

MOV A, HUNDREDS; SEGMENT 4

CJNE A, # 0h, CONTINUES

MOV A, # 0FH

KEEP: ADD A, # 80h

SWAP A

MOV P1, A

ACALL DELAY

RET

SET_START: MOV MENU_OK, # 0h; 1 = MENU, 0 = OK

MOV D_SETING1, # 0h

MOV D_SETING2, # 0h

MOV D_DISPLAY1, # 0h

MOV D_DISPLAY2, # 0h

RET

DELAY: MOV 42H, # 2H

LAGI_1: MOV 43H, # 0FAH

LAGI_2: DJNZ 43H, LAGI_2

DJNZ 42H, LAGI_1

RET

DELAYT: MOV 42H, # 0A0H

AGAIN_3: MOV 43H, # 0F0H

AGAIN_4: DJNZ 43H, AGAIN_4

DJNZ 42H, LAGI_3

RET

END

Hopefully useful and can help or give an idea of making a program to control temperature egg incubators using the microcontroller

HiFi Headphone amplifier

HiFi Headphone amplifier

Read More..

|

| HiFi Headphone amplifier |

Subscribe to:

Comments (Atom)