The electronic circuit is a TV modulator that is really no more than a transmitter. It is a very small transmitter, admittedly, but none the less that is what it is. What does a modulator actually do? In general -and this design is no exception to the rule - it is a simple oscillator that generates a frequency somewhere in the VHF or UHF region. The oscillator is modulated with the video signal and the modulated carrier wave thus generated is fed into the TV sets aerial input via a cable. Then all that remains to do is tune the TV to the correct frequency.

Circuit Schematic

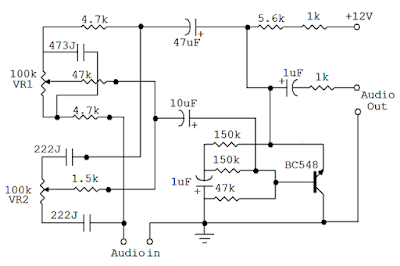

The crystal oscillator is based on a very fast HF transistor, Tl (BFR91), which performs the amplitude modulation. Apart from this there is little to be said about the oscillator except, perhaps, that it is essential to use the correct values for the components surrounding Tl. This is, of course, simply common sense in this sort of HF circuit.

The harmonics generator is formed by two Schottky diodes, Dl and D2. These diodes must switch very quickly in time with the 27 MHz signal so they provide strong harmonics up into the gigahertz range. The modulation depth can be set with Pl, while the oscillators d.c. value can be varied by means of P2. The combination of these two presets enables either positive or negative amplitude modulation to be selected.

This is essential as the harmonics produced vary in this respect. We will discuss the calibration of Pl and P2 later in this article. The power for the circuit can be provided by either an unstabilized 8...30 V or a stabilized 5 V. The latter could be taken from a computers power supply and in this case ICI is not needed.

The printed circuit board for the modulator is only single-sided. The largecopper surface acts as a ground plain.

Parts list

Resistors:

R1, R2 = 4k7

R3, R4 = 56ohm

P1 = 100 ohm preset

P2 = 500 ohm preset

Capacitors:

C1 = 4mf7/16 V

C2= 10p

C3 = 220p

C4 = 47p

C5 = 47n, ceramic

C6 = 100n*

C7 = 330n*

Inductors:

L1, L2 = 3.5 turns of 0.2 mm (SWG 35 or 36) CuL on a ferrite bead of about 3.5 x 3.5 mm

L3 = 1 microH

L4 = 1 turn of 0.8. . .1 mm (SWG 19...21) CuL, air wound with a diameter of 8 mm

Semiconductors:

D1, D2 = 1N6263 (Ambit/Cirkit)

D3 = lN4148

T1 = BFR91 (Ambit/Cirkit)

IC1 = 7805*

Miscellaneous:

X1 = crystal, 27 MHzd(3rd overtone) or other 3rd overtone crystal between 25 and 30 MHz

*= not needed if the circuit is powered from a stabilised 5 V supply